Hydro Milling Group Is One Of The Pioneering Companies In The Aqua Milling Arena.

SEE BEFORE & AFTER

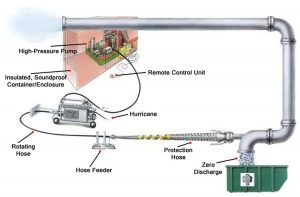

Hydro-milling, also known as Aqua-Milling or Aqua-Lazing, is an efficient method of cleaning industrial piping through the implementation of HMG high pressure water pump system, HMG Hurricane Pipe Cleaning System, and HMG specialized nozzles and jets.

Newly installed process piping typically contains large amounts of foreign debris, mill scale, rust deposits, sand, dirt, and other construction debris. These residual deposits can potentially compromise system reliability and lead to premature system degradation and catastrophic failure during plant operation. In order to help preserve the long-term integrity of these process piping systems, hydro-milling can be used to remove all undesirable foreign contaminants and particulate matter. Hydro-milling has been proven as an effective means of removing both large and fine debris from piping surfaces, piping systems and vessels, including post-construction debris, byproducts that result during fabrication, and operation-derived deposits, which are comprised of welding slag, mill-scale, loose rust, and mineral sediment.

During the hydro-milling process, water is pumped at high pressure from Hydro Milling Groups high-pressure pump units, through a self-propelled high-pressure nozzle engineered for pipe wall cleaning at service pressures between 5000 to 21,500 psi (~35,500 kPa to ~148,237 kPa). The attached hose is then sent through a bi-directional feeder and rotated at operator-controlled rates into the piping. The rotational motion of the hose allows the nozzle to easily negotiate 90° elbows, piping turns, and multi-directional changes, in addition to providing full surface area cleaning throughout the entire pipe circumference. Complex vertical and horizontal lengths of pipe with diameters between 2” to 50” are easily traversed with full cleaning capacity. Smaller diameter piping can also be cleaning using HMG specialized cleaning methods. Simple horizontal straight-length pipelines with diameters exceeding 48” can also be cleaned sufficiently. Hydro-milling has the capability of providing a 1250 ft. horizontal and/or 350 ft. vertical cleaning spread.

All loose debris is efficiently driven out of the system through the intelligent operation of the in house engineered Hurricane Pipe Cleaning System and HMG specialty all cutter nozzles. By withdrawing the high-pressure nozzle during operation, all debris is pushed out of the line in a predictable and controlled manner. When equipped with auxiliary heating, hydro-milling can also be performed in subzero conditions.

As guidelines to meet more demanding environmental regulations, Hydro Milling Group, Inc., is dedicated to providing services that adhere to all client protocols. In cases where stringent environmental and waste disposal regulations call for reduced water usage, hydro-milling setup can be outfitted with supplementary filtration skids to recycle all waste effluent. In situations where clean demineralized water is limited, HMG has the ability to filter and recycle the used demineralized water to obtain maximum usage prior to disposal. In some cases the recycled water then can be used as dust control.

Hydro Milling Group is strongly committed to providing its services in the safest manner possible, with minimal impact to the environment, our employees, contractors, clients, and the general public. Meticulous planning and engineering goes into each hydro-milling assignment. Furthermore, anti-withdrawal, pressure discharge, and restraining devices are installed to control and mitigate all hazards.

Hydro Milling Group is strongly committed to providing its services in the safest manner possible, with minimal impact to the environment, our employees, contractors, clients, and the general public. Meticulous planning and engineering goes into each hydro-milling assignment. Furthermore, anti-withdrawal, pressure discharge, and restraining devices are installed to control and mitigate all hazards.

When compared to more traditional water flushes or steam blows, hydro-milling can match or exceed cleanliness specifications while reducing the time and costs associated with the manufacture of required demineralized water, consumed fuel to manufacture steam required steam for steam blows, eliminate steam blow noise, waste disposal, scheduling, and equipment requirements.

WHY CHOOSE THE HYDRO MILLING GROUP

Hydro Milling Group Inc is dedicated to providing the most technologically advanced industrial services available to the power, process, petrochemical, chemical, and oil and gas industries. We constantly research the latest techniques and develop methods in order to continuously provide the leading standards in industrial cleaning services. We are experts in determining the best methods for pre-commissioning cleaning services and tailor those methods or combination of methods in order to obtain the best outcome to our client’s needs.