Hydro-Milling Group systems use the latest technology in high-pressure water to alleviate the problems faced by companies who utilize process pipeline in industrial applications. Our customers’ needs vary from removing mill scale and debris in power generation plants to clearing blockages in refineries, petro-chemical plants, paper mills and aluminum manufacturing plants.

Our Hydro Milling Process

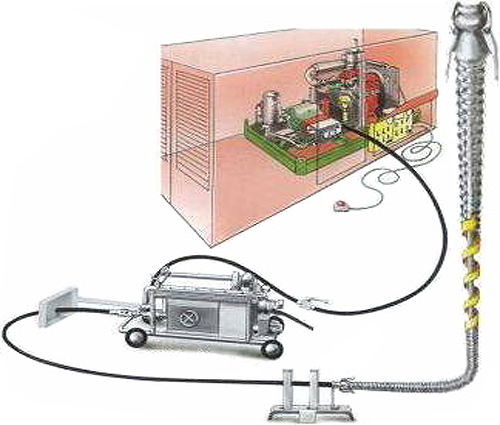

The hydro milling process utilizes water that is pumped at high pressure through a self-positioning self-propelled high pressure nozzle; this nozzle moves along pipe wall in a mechanically and repeatable motion providing cleaning with working pressures between 5000 to 21,500 psi (~35,500 kPa to ~148,237 kPa). The attached hose is then fed through a rotational hose feeder to provide precise rotary motion along the inner surface of the pipe. The rotating hose is fed through a stainless steel safety hose removing the chance of hose from backing out of the piping structure. Once in the pipe, the operator-controlled rotating hose allows the nozzle to easily negotiate multiple 90° elbows and pipe offset to distances of 350 feet (~106m) vertically or 1,250 feet (381m) horizontally from the point of entry with precise tracking capabilities to providing full surface area cleaning throughout the entire pipe. All debris and mill scale removed from the pipe surface is transported out of the pipe when the high-pressure nozzle is retracted. This is accomplished via the pusher/flusher orifices built into the cleaning nozzle, utilizing the typical working pressure with an average flow up to 50 GPM (189 LPM) to be efficiently flush the mill scale and residue from the system. All resulting effluent and debris can then be contained and collected for proper disposal. Our hydro-milling equipment can be properly outfitted to operate in severe conditions from subzero (-31˚F ~ -35˚C) to dessert conditions (135˚F ~ 57˚C) ambient.

Hydro Milling Video

Equipment

Hydro-Milling Group rigs arrive on site complete with a mobile control room/office at no charge to the client. HMG uses the latest technology available to thoroughly remove all mill scale and debris from the various steam system piping at your site location. This is accomplished with the Kamat 350 KW High-Pressure Pump and Hurricane Rotating System detailed below.

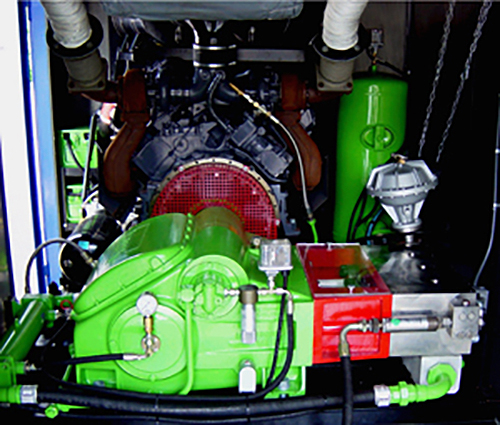

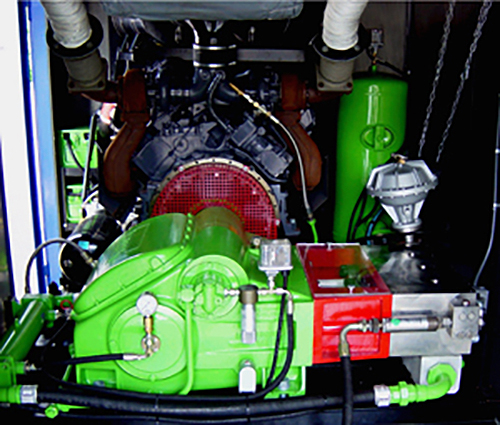

Hammemman 350-500 KW High-Pressure Pump

- Powered by a 510-670 HP continuous duty diesel engine

- Capable of pressures up to 21,500 PSI

- Water volume rates to 45-53 GPM

- Enclosed within an industrial, sound insulated steel container

- Advanced water flow control panel

Hammemman 350-500 KW High-Pressure Pump

- Powered by a 510-670 HP continuous duty diesel engine

- Capable of pressures up to 21,500 PSI

- Water volume rates to 45-53 GPM

- Enclosed within an industrial, sound insulated steel container

- Advanced water flow control panel

Kamat 380 KW High-Pressure Pump

- Powered by a 510 HP continuous duty diesel engine

- Capable of pressures up to 21,500 PSI

- Water volume rates to 61 GPM

- Enclosed within an industrial, sound insulated steel container

- Advanced water flow control panel

Kamat 380 KW High-Pressure Pump

- Powered by a 510 HP continuous duty diesel engine

- Capable of pressures up to 21,500 PSI

- Water volume rates to 61 GPM

- Enclosed within an industrial, sound insulated steel container

- Advanced water flow control panel

Hurricane Rotating System

- Precise control of rotation of cleaning nozzle within pipe

- Precise advancement of cleaning process through pipe

- Vertical travel of cleaning process to 350 feet from entry point

- Horizontal travel of cleaning process to 1250 feet from entry point

- Cleaning nozzle has the ability to traverse multiple 90-degree elbows and multiple changes of direction

Hurricane Rotating System

- Precise control of rotation of cleaning nozzle within pipe

- Precise advancement of cleaning process through pipe

- Vertical travel of cleaning process to 350 feet from entry point

- Horizontal travel of cleaning process to 1250 feet from entry point

- Cleaning nozzle has the ability to traverse multiple 90-degree elbows and multiple changes of direction

Working Together…

The tremendous power of the Kamat High-Pressure Pump is coupled with the Hurricane Rotating System, the latest state-of-the-art pipe cleaning system that has been designed to provide superior pipe cleaning under any conditions. Together, these two systems bring about great results in the most expedient and safest manner possible.

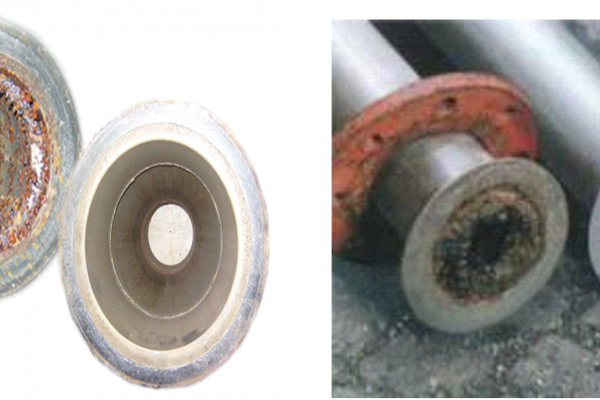

Before Mill Scale Removal

After Mill Scale Removal

Working Together…

The tremendous power of the Kamat High-Pressure Pump is coupled with the Hurricane Rotating System, the latest state-of-the-art pipe cleaning system that has been designed to provide superior pipe cleaning under any conditions. Together, these two systems bring about great results in the most expedient and safest manner possible.

Before Mill Scale Removal

After Mill Scale Removal

Before & After Examples

Hydro-Milling Group systems use the latest technology in high-pressure water to alleviate the problems faced by companies who utilize process pipeline in industrial applications. Our customers’ needs vary from removing mill scale and debris in power generation plants to clearing blockages in refineries, petro-chemical, and aluminum manufacturing plants.