Involved Systems:

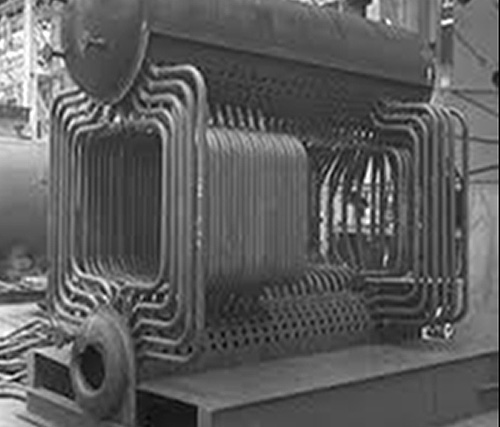

- All industrial water systems, all steam systems, gas production, industrial gas delivery, medical gas delivery, Heat Recovery Steam Generators (HRSG), boilers

Commissioning Services:

- Flushing of all systems to clear construction debris

- Process drying of piping

- Boil-out

- Steam blow cleaning of systems

- Chemical cleaning

- Pressure testing

Maintenance Services:

- Reduce scale loading in water systems

- Improve efficiency in the heating or cooling system

- Heat exchanger cleaning

- Post tube replacement cleaning

- Routine outage